Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

MT

CHUANYA

7310299000

1

US $100/ Piece

Wooden

Stainless Steel

Water

L/C, T/T

1000PCS/ Month

Mirror Polish, Electro Polish Ra<0.4um

Low Temperature Storage & Transportation Equipment

Environmental Protection, Chemical Industry

1.0MPa

CE, SGS, ISO 9001

Ss 304/316/316L

Electric Power

Flange

0~250c

Ningbo, China

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

Stainless Steel Food Pressure Mixing Tanks for Water Storage and Food Beverage

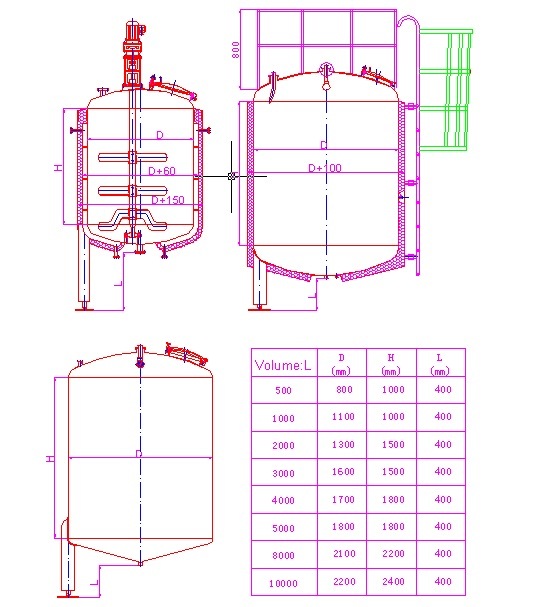

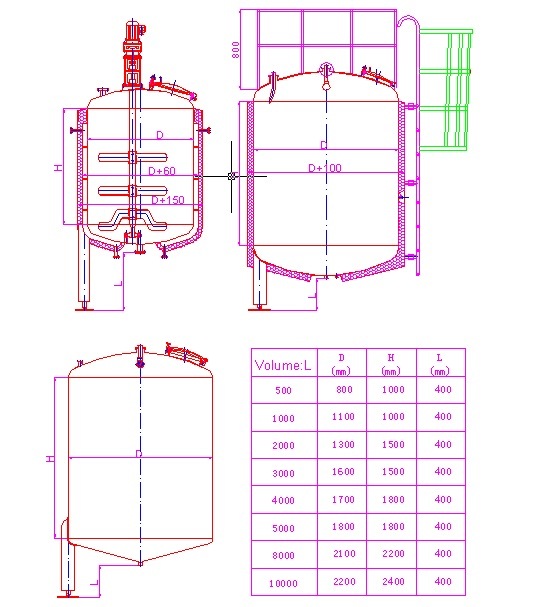

A stainless tank can require ASME certification at certain temperatures and pressures. If heating dead spots must be eliminated in any of your stainless steel mixing tanks, CHUANYA's manufacturing includes an innovative bottom dimple jacket that does just that with still one inlet and outlet on the stainless tank. Our fiberglass insulation and stainless sheathing insure a spectacular finish and increased safety. Another challenge in stainless steel mixing tanks is applying the correct surface finish. CHUANYA can work with you to find the right finish for your application. We can achieve something as precise as a single digit Ra finish with passivation and electropolish, to something as cost effective as a 2B mill finish and anything in between on stainless steel mixing tanks. Achieving the right surface finish is crucial to limit bacterial growth in biological applications and cleaning time in all stainless tank applications.

Feature

| Parameter | Model | CYGCD-75 | CYGCD-150 | CYGCD-300 | CYGCD-600 | CYGCD-1000 | CYGCD-2000 |

| Effective volume:L | 75 | 150 | 300 | 600 | 1000 | 2000 | |

| Barrel | Diameter:mm | Ф250 | Ф600 | Ф800 | Ф1000 | Ф1100 | Ф1300 |

| Height:mm | 460 | 550 | 600 | 800 | 1000 | 1500 | |

| Mixing | Motor power:KW | 0.37 | 0.55 | 0.75 | 0.75 | 1.1 | 1.5 |

| Mixing work RPM :r/min | 200(propeller) (The design can be adjusted according to customers' usage) | ||||||

Stainless Steel Food Pressure Mixing Tanks for Water Storage and Food Beverage

A stainless tank can require ASME certification at certain temperatures and pressures. If heating dead spots must be eliminated in any of your stainless steel mixing tanks, CHUANYA's manufacturing includes an innovative bottom dimple jacket that does just that with still one inlet and outlet on the stainless tank. Our fiberglass insulation and stainless sheathing insure a spectacular finish and increased safety. Another challenge in stainless steel mixing tanks is applying the correct surface finish. CHUANYA can work with you to find the right finish for your application. We can achieve something as precise as a single digit Ra finish with passivation and electropolish, to something as cost effective as a 2B mill finish and anything in between on stainless steel mixing tanks. Achieving the right surface finish is crucial to limit bacterial growth in biological applications and cleaning time in all stainless tank applications.

Feature

| Parameter | Model | CYGCD-75 | CYGCD-150 | CYGCD-300 | CYGCD-600 | CYGCD-1000 | CYGCD-2000 |

| Effective volume:L | 75 | 150 | 300 | 600 | 1000 | 2000 | |

| Barrel | Diameter:mm | Ф250 | Ф600 | Ф800 | Ф1000 | Ф1100 | Ф1300 |

| Height:mm | 460 | 550 | 600 | 800 | 1000 | 1500 | |

| Mixing | Motor power:KW | 0.37 | 0.55 | 0.75 | 0.75 | 1.1 | 1.5 |

| Mixing work RPM :r/min | 200(propeller) (The design can be adjusted according to customers' usage) | ||||||

WhatsApp:+8618058865291

Email: wzchuanya@gmail.com